Metallics

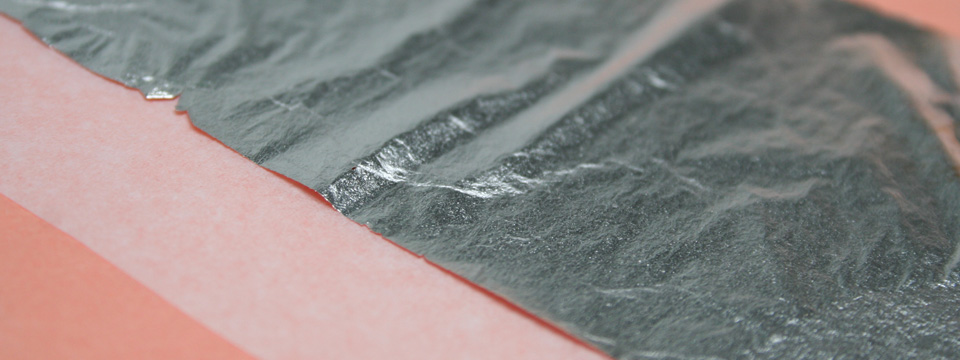

Metal leaf

Origin of metallic decorative surfaces

Metallic surfaces have their origin in the tradition of gilding. The gilding trade is an old venerable craft technique of applying wafer-thin metal sheets to different, specially treated substrates.

These precious, mysteriously shimmering surfaces were used, for example, in book art, icon painting, gilding in sacral areas, refinement of figures or coats of arms and much more. The age-old way of surface design was mostly carried out using oil or poliment technique (Gesso). Even today, they are still practices in exactly the same way.

Metal leaf is a metal that is formed into very fine leaves by beating or rolling. Gold alloys in particular are used as leaf metal (gold leaf). Instead of expensive, genuine gold, imitation gold was used - usually bronze or brass. These imitations are also called composition gold, Dutch metal or Schlagmetal. By the way, in addition to gold shimmering surfaces, there are also metals of other colours for surface refinement, such as silver or aluminium leaf.

Thanks to the development of new materials, we are now able to produce metallic-looking surfaces in a variety of ways, such as with our products Capadecor Metallocryl, CapaGold and CapaSilber.

In an interview:

The companies Steuernagel and Lampert Baudekoration from Groß-Bieberau, for example, offers surface finishing with metal leaf.

Mr. Held, master of sculpture painting and gilding, is at work together with two journeymen. Here are four questions for Mr. Held:

Are there still requests for gilding these days?

Gilding and leaf metal are still in demand. Recently, the demand has even increased. Especially in the field of monument preservation, these surfaces are indispensable. Typical objects for gilding are, for example, weathercocks, metal elements such as spheres, furniture restorations or picture frames. In the private sector, too, such surfaces are often used as a special highlight.

Which metals are primarily used?

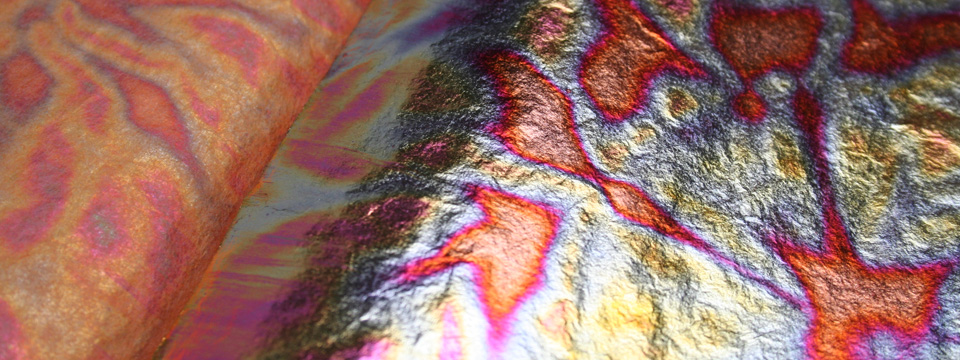

Besides real gold, aluminium, silver, copper, bronze, and brass are often used. Recently, oxidised surfaces have become very popular, such as oxidised or patinated copper and silver. They allow you to create very exciting effects and unusual colours.

A distinction is made between poliment gold plating and oil gold plating. For both techniques, not only gold but also the other metals are used. In poliment gilding, the colour of the substrate plays an important role, because the colour shines through after the final treatment (rubbing). You can also vary the structure and gloss levels of the surface.

This means you have an infinite number of design options. In our workshop, we like to experiment and develop new surface finishes.

What makes surfaces with metal leaf so special?

The visual appearance is unique due to the 100% metal content of the surfaces refined with metal leaf: the play with light and shadow, the gleam, the shine, the depth effect make these surfaces so special.

As in earlier times, it is primarily the appearance that is decisive when selecting the metal. Function and price also play a role, of course. Gold-like metals such as bronze or brass are many times cheaper than real gold. However, the design aspects still take precedence over the monetary aspects to this day. For example, the colour of the respective metal.

The specific properties of metals also play a major role in their use: brass, for example, has an antiseptic effect and was therefore often used for door handles in public buildings. When it comes to weather-resistant surfaces, gold leaf is still used today, because with 23 ¾ carat gold does not oxidise.

What are the exciting projects you have been working on lately?

Recent projects in Frankfurt include the Grand Hotel, the Pure Training fitness studio and, above all, the Festhalle on the exhibition grounds, where we gilded the entire railing.