Metallics

Micaceous Iron Oxide for Metals

Corrosion protection and the look of the DB colours

UV radiation, air pollution, chemicals or petrol. Micaceous iron oxide paints are used wherever maximum corrosion protection is required. And all this, although micaceous iron oxide is a purely natural product. So why is iron oxide such an excellent rust protection pigment?

Scaled Shell Colour Is Going Strong

Micaceous iron oxide varnishes and micaceous iron oxide paints have a scaly structure. Their pigments are also called "scale armour paint". The paint covers the surface to be protected like a scale armour. Corrosion is greatly reduced where his paint is used. Steel bridges, power poles, even the Berlin TV Tower and the Eiffel Tower are protected against all weathers with this paint.

Also Visually a Brilliant Achievement

Thanks to its metallic effect, the mica paint is also very much appreciated visually. This is because micaceous iron products sparkle. Architects are increasingly using them in private residential buildings. Here, the robust surface with an attractive glittery look usually serves to protect and design railings or the like.

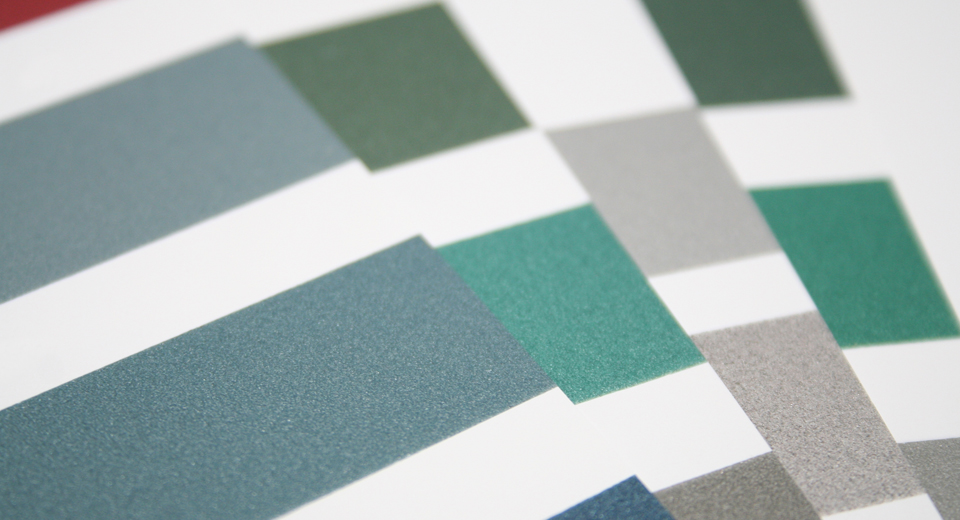

The Colour Nuances

Iron mica products generally have a grey appearance due to their high proportion of micaceous iron oxide. Such greyed shades characterise micaceous iron oxide paints. This type of paint does not come in pure, bright colours.

In practice, a colour selection based on the colour chart of Deutsche Bahn has established itself. Micaceous iron oxide paint is usually produced according to the so-called "DB shades". In the Deutsche Bahn area, the DB colour chart is mainly used to display the colours for steel components such as steel bridges, railings or platform roofs. In contrast to the colours of the RAL colour system, these colours contain the effect pigment "micaceous iron oxide".

DB colours can also be found in our LackChamp.

Paint metal railings in DB shades, for example with Capalac Dickschichtlack.